chocolate to ketchup: Humans drive change

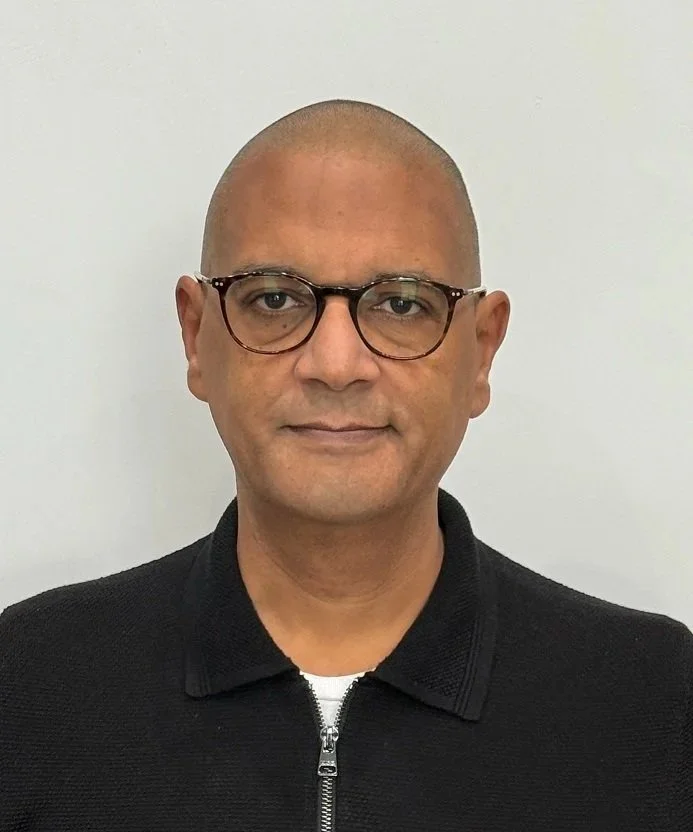

Ahmed El Gabry’s two-decade career has taken him from Cairo to global boardrooms, reshaping supply chains and building high-performance teams across three continents. As former VP of Strategy & Transformation at Kraft Heinz, and with senior leadership roles at Mars, Godiva, and MAESA, Ahmed has engineered operational turnarounds and spearheaded digital supply chain innovation, earning a reputation for turning strategy into measurable results.

Ahmed shares how moving from finance to managing factories in Egypt and, to leading teams in New York shaped his worldview. He opens up about learning to “win hearts and minds” and why investing in people is the real differentiator in transformation. Also discover how a simple product like Snickers symbolizes the sophisticated, layered nature of his international career.

Candid stories, honest lessons, and practical advice make this a must-listen for any professional ready to rethink what leadership in supply chain truly means

Derek Lutz: Can you talk about how you moved from the Middle East to the US and your journey into supply chain?

Ahmed El Gabry: I'm originally from Egypt and started my career there, first in finance, then moving into operations and eventually supply chain. Over the last three decades, I’ve worked around the globe, shifting from small businesses to large-scale organizations. Although I started in finance to better understand business, I fell in love with operations and spent the rest of my career there, including time as a general manager.

Derek Lutz: What’s a moment where culture completely flipped your playbook or made you rethink your approach in supply chain?

Ahmed El Gabry: When I moved to MARS, I came from organizations that were very KPI- and performance-driven. At Mars, I realized success was about winning hearts and minds—aligning stakeholders and moving together. That shift in culture was transformative for me.

Derek Lutz: When did you realize that supply chain could deeply impact people’s lives beyond just moving product?

Ahmed El Gabry: My first plant manager role in Egypt was pivotal. As a finance guy on the shop floor, I asked simple questions, which made people comfortable. The authenticity and commitment of the team struck me, and I saw how treating people with respect extended beyond the factory to their families and lives.

Derek Lutz: You’ve led a lot of transformational change. What’s harder: fixing a broken supply chain or transforming a company that doesn’t know it’s broken?

Ahmed El Gabry: Transforming a company unaware of its own challenges is by far harder. Clarity in strategy and purpose is essential; without that, fixing the supply chain is almost impossible.

Derek Lutz: How is shifting from chocolate to beauty different for supply chain leaders? What’s the difference between working in large versus small organizations?

Ahmed El Gabry: Personal care is far more volatile and complex than chocolate. The number of items and the uncertainty are higher. Although core supply chain skills are transferable, smaller companies force you to build capabilities and processes from scratch—unlike large companies, which have established systems.

Derek Lutz: Transformation is a hot topic. What is most overlooked in transformation programs?

Ahmed El Gabry: The hardest part is the human transformation. Everybody says ‘people first’, but in practice, too few resources and attention go into truly preparing and empowering teams for change—that’s why many initiatives don’t stick.

Derek Lutz: What differentiates talent that thrives in supply chain from talent that burns out?

Ahmed El Gabry: Attitude and curiosity are more important than technical ability. Success is about willingness to learn, vulnerability, collaboration, and knowing your value—but also getting well with the team and seeking help when needed.

Derek Lutz: What’s the best “bad decision” you’ve made—one that seemed like a mistake but turned out to teach valuable lessons?

Ahmed El Gabry: Implementing a major system across every process in an organization that wasn’t ready brought immense pain but surfaced strategic challenges that needed to be addressed, triggering a deep overhaul in how the business was managed.

Derek Lutz: You’ve built supply chains in all sorts of places. What’s the strangest or most memorable location this career has taken you?

Ahmed El Gabry: My first plant management role took me to a tiny and remote village factory in France, total culture shock. But the most fascinating place has to be Japan. Culturally, it’s unlike anywhere else I’ve worked.

Derek Lutz: Of all the products you’ve helped bring to market, which one tells your story best?

Ahmed El Gabry: Snickers. It looks simple but is one of the most complex products, a reflection of my own international, multi-layered career.

Derek Lutz: If you could put a new factory anywhere in the world, where would it be?

Ahmed El Gabry: Egypt for cost efficiency, China for speed, and Mexico as a mix of both. But my heart leans toward Egypt.

Derek Lutz: If we strip away titles and achievements, who is Ahmed at his core?

Ahmed El Gabry: Wholehearted. I don’t do things halfway. If I commit, it’s 200%. Family, friends, integrity, and trust are fundamental, and I strive to enable those around me to do their best.