Generational Compensation Trends

Forget the old playbook that treats everyone the same. If leaders want to take retention seriously, they need to get granular, because Gen X, Millennials, and Gen Z all have different ideas about what “fair reward” means, and leading organizations are responding with surprisingly inventive solutions.

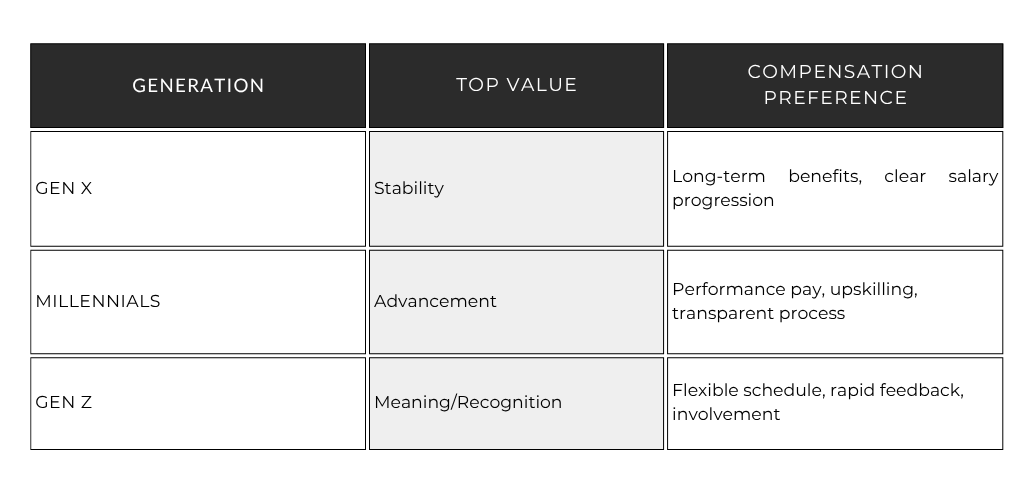

How Each Generation Sees Compensation

Generation X

Born in the 1960s and 70s, Gen X still tends to value stability and long-term safety. Think robust medical plans, pension schemes, and clear recognition for tenure or loyalty. In the supply chain, this preference is reflected in a desire for predictable salary growth, steady incentives based on years of service, and benefits that make life easier (sometimes it’s a company van or a top-tier health policy that seals the deal).

Millennials (Gen Y)

For Millennials, compensation isn’t just a paycheck; it’s a signal. They love advancement opportunities, and the chance to grab new skills or leadership roles matters just as much as the raise. These professionals are typically more responsive to performance-based incentives, transparent salary structures, and workplaces that promote autonomy and collaboration. In the supply chain world, this translates to fast-track promotion tracks, upskilling budgets, and clear visibility into how their input moves the business forward.

Gen Z

Now, get ready for a curveball. Gen Z, those entering the workforce after 2000, often view salary as just one small part of the total package. They rank it behind advancement opportunities, flexibility, psychological safety, and meaningful work. This generation isn’t interested in just punching in and out; they want rapid recognition, two-way feedback, inclusive environments, and employers who care about social impact. In supply chain and logistics, Gen Z’s appetite for tech-driven training, gig-style flexibility, and micro-achievement rewards is reshaping everything from roles to shift scheduling.

Chart: Generational Compensation Preferences in Supply Chain

Survey Evidence and Real-World Examples

In US supply chain operations, some companies ditched rigid 50-job classification systems for “four-level” pay bands, but carved out extra sub-levels for achievement (think technician progressions like 1a/1b/1c). Employees advance rapidly but must pass rigorous certifications for every jump. In one benchmark, a role-rotation system moved talent every 18 months, based on skill rather than seniority.

Flexibility in action: When logistics teams struggled with unreliable employee transportation, the company added $100/month in ride-share gift cards (25% of employees used the benefit), resulting in a decrease in absenteeism. Scheduling apps that allow staff to select their own shifts have made part-time roles viable, attracting Gen Z and Millennials who value autonomy.

What Makes Supply Chain Unique

Supply chain professionals are wired a little differently; they’re always balancing precision and chaos, as well as collaboration and independence. When it comes to compensation:

They value clear impact: Bonuses or equity tied to actual supply chain performance (think fill rate or on-time delivery) matter far more than generic “company-wide” targets.

Risk and resilience premiums: In inflationary, high-volatility markets, experts expect retention premiums for those in logistics, planning, and procurement—jobs seen as business-critical.

Training as currency: Unlike some sectors, supply chain teams actively trade upskilling for loyalty. Practical certifications, such as Six Sigma or ERP mastery, are now tied to pay bands and used as effective retention levers.

Recognition for adaptability: Supply chain teams, especially in frontline and logistics environments, respond strongly to “micro-achievement” rewards, spot bonuses for solving a transportation crisis, peer recognition for process improvements, or extra PTO for a flawless quarter.

What Leading Employers Are Doing

Individualized roadmaps: Employers tailor advancement tracks and compensation packages. One large supply chain organization set up “menus” for career growth: some chose leadership training, others switched departments for broader exposure, and some could request a self-demotion if promotions exceeded their capacity.

Hyper-flexible benefits: Standard PTO is out; variable scheduling, shifting hours, and even flexible leave for medical or personal needs are in. Teams create their own operating processes to meet both team and business requirements, trading rules for principles.

Tech-enabled feedback: Real-time, app-based performance dialogues—rather than annual reviews—became the norm, helping Gen Z and Millennials see immediate progress and correction. Certification ladders and instant recognition boost morale and retention.

Focus on diversity and social impact: Gen Z, in particular, wants to work for employers that put real money behind social initiatives—such as climate-friendly supply chains, inclusive hiring, and even direct ESG bonuses tied to project outcomes.

Strategic Takeaways for Retention

Don’t standardize, personalize: Meet generational and personal needs with layered pay systems, flexible perks, and bespoke development tracks.

Keep measuring and asking: Be relentless about pulse surveys, team feedback apps, and compensation benchmarking, especially for the hardest-to-fill roles in supply chain.

Tie compensation to action: Rewards must follow rapid achievement cycles and recognize tangible impact, especially in dynamic, high-touch areas like logistics and manufacturing.

Put culture front and center: The value of belonging and purpose rises every year, especially among Gen Z and Millennials. Compensation, benefits, development, and recognition are all best delivered “in real time,” woven into the fabric of a genuine, people-first culture.

Leading organizations are embracing this new complexity, treating compensation as both art and science designed for maximum retention across every cohort in the current hyper-competitive talent market.